-

Conexões de Tubulação de Titânio

-

Tubulação soldada titânio

-

Flange de Tubo de Titânio

-

Tubo de titânio sem costura

-

Permutador de calor do titânio

-

Tubulação da bobina do titânio

-

Folha da liga do titânio

-

Fixadores de titânio

-

Fio de Soldagem de Titânio

-

Barra redonda do titânio

-

Forjados de titânio

-

Cobre folheado do titânio

-

Elétrodo do titânio

-

Metal que engasga o alvo

-

Produtos do zircônio

-

Filtro poroso aglomerado

-

Fio de Nitinol da memória da forma

-

Produtos de nióbio

-

Produtos do tungstênio

-

Produtos do molibdênio

-

Produtos de tântalo

-

Produtos de equipamento

-

produtos de alumínio

-

produtos de aço inoxidável

Sintered Plate Inconel600 Titanium SS 316L For Filtration And Separation

| Lugar de origem | CHINA |

|---|---|

| Marca | CSTY |

| Certificação | GB/T19001-2016/ISO9001:2015 |

| Número do modelo | SS 316L |

| Quantidade de ordem mínima | 10kgs |

| Preço | $80.00 - $110.00/ Piece |

| Detalhes da embalagem | Embalagem de papel e caixa de madeira, embalagem de cartão pode ser de acordo com os requisitos do c |

| Tempo de entrega | 15 ~ 20 dias de trabalho |

| Termos de pagamento | L/C, T/T, Western Union, MoneyGram, PayPal |

| Habilidade da fonte | 5000 kg/kg por mês |

Contacte-me para amostras grátis e vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

x| Precisão da filtração | 0.1um | Resistência à abrasão | Alto |

|---|---|---|---|

| característica | Utilizado em ambientes altamente corrosivos | Área de filtração | 0.3-1.0m2 |

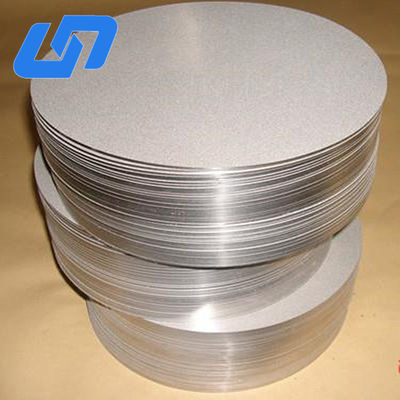

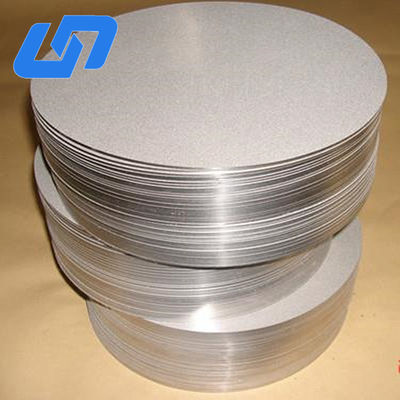

| Especificação | 0.5um, 2um, 5um, 10um, | Diâmetro | 50-1000 mm |

| Material | Titanium, SS 316L, Inconel600, etc. | Serviço da amostra | Forneça a amostra testando |

| Tipo | Metal, SS Filter Disc | Padrão | ISO9000 |

| Pressão de trabalho | 2-3Mpa | Embalagem | Pacote de exportação padrão |

| Vida de serviço | 2-5 anos | Pressão máxima | 2.0Mpa |

| Dimensão | Personalizado | ||

| Destacar | Placa filtrante porosa sinterizada de Inconel600,Placas de filtragem sinterizadas de titânio,Placa de separação sinterizada SS 316L |

||

Introduction

Compared with traditional filtration materials such as paper, cotton, PP, PE, PES, and PTFE, metal powder sintered porous materials offer superior performance. They provide excellent permeability, precise pore size control, stable shape, high filtration accuracy, wear resistance, good mechanical strength, and excellent heat conduction and dissipation.

Moreover, sintered metal materials can withstand high temperatures, maintain their shape under stress, and be cleaned and reused multiple times, making them a durable and cost-effective filtration solution.

Specifications

| Product Name | Sintered Plate |

|---|---|

| Material | Pure Titanium / SS316L / Bronze / Inconel 600 |

| Size | OD 20–80 mm × WT 2.5–3.0 mm × L 10–1200 mm |

| Filter Accuracy | 0.5–80 µm |

| Connection | Customized according to customer requirements |

| Applications | Sparging, Separation and Filtration, Carbonation, Liquid Filtration, etc. |

Technical Parameters

| Filter Accuracy (µm) | Porosity (%) | Permeability (m³/m²·h·kPa) | Compression Strength (MPa) | Temperature Tolerance (°C) | Max Working Pressure (MPa) |

|---|---|---|---|---|---|

| 0.5–50 | 20–50 | 3–800 | 2–3 | 250 | 0.6 |

Applications

The sintered plate is widely used in industries including electronics, water treatment, food and beverage, biotechnology, chemicals, petrochemicals, metallurgy, and gas purification. It represents a new generation of filtration materials with broad development potential.

Typical applications include:

-

Sparging

-

Separation and Filtration

-

Carbonation

-

Liquid Filtration

-

Catalyst Recovery

-

Steam Filtration

-

Slurry Oil Filtration

-

Flame Arrestors

-

Sound Silencing

-

Fluid Distribution and Control

-

Semiconductor Manufacturing

-

Fuel Cell Stacks

-

Coating Electrodes

-

Damping and Shock Absorption

-

Heat Exchange

-

Bio-Implants

Properties

-

Uniform pore size and stable pore structure with high separation efficiency

-

High porosity, low filtration resistance, and excellent permeability

-

Outstanding chemical stability and resistance to acids, alkalis, and oxidation

-

Morphological stability—no particle shedding; compliant with food hygiene and pharmaceutical GMP standards

-

Strong mechanical properties, low differential pressure, and large flow capacity

-

Excellent anti-microbial characteristics, non-reactive with microorganisms

-

Easy online regeneration, backwashing, and long service life

-

Excellent biocompatibility for use in biological, food, pharmaceutical, and medical applications

-

Effective electromagnetic shielding performance

-

Strong damping and shock resistance